Purificador seco de gases de escape AOSIF

El producto purificador utiliza (DPF) como soporte del filtro, que puede atrapar partículas de humo negro PM en los gases de escape.

1.DPF: la trampa de partículas de flujo de la pared del motor diesel adopta un elemento de filtro portador de cerámica DPF, DPF (abreviatura de filtro de partículas diesel)

1.1 La trampa de partículas de flujo de la pared del motor diesel es un producto nuevo que puede eliminar eficazmente las partículas de humo negro del escape del motor diesel.

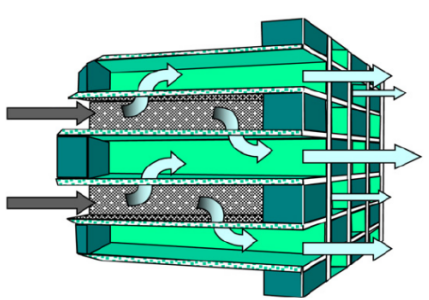

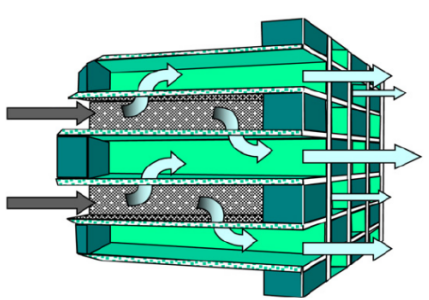

2. Flujo de trabajo de filtrado de DPF:

DPF utiliza las particiones porosas entre los canales de panal bloqueados alternativamente para atrapar las micropartículas de humo negro PM en el escape de diesel.

motor diesel El humo negro que contiene partículas de carbono descargadas durante

La operación ingresa a la trampa de partículas DPF de escape del motor a través de un tubo especial y lo atraviesa.

Los filtros densamente dispuestos absorben las partículas de hollín del filtro de cerámica.

La trampa de partículas de escape del motor diesel adopta un portador de cerámica DPF,

El cuerpo cerámico de tipo filtro está compuesto por muchos pequeños poros paralelos; Estos poros paralelos están separados por paredes de poros permeables al aire, un extremo

Abierto, un extremo está bloqueado, los microporos en la pared del orificio del filtro pueden permitir que se descarguen los gases de escape

del motor diésel, y las partículas de humo negro se deben a la relación de tamaño de partícula

Es más grande y no puede atravesar los microporos,

y se filtra sobre la superficie de la pared de poros de cerámica para lograr el efecto de eliminar el humo negro.

El motor diesel funciona por un período de tiempo. Posteriormente, las partículas de carbón interceptadas deben limpiarse con regularidad.

3. Rendimiento del producto:

El DPF tiene una gran capacidad para atrapar nanopartículas ultrafinas de humo de carbono, así como alta resistencia al calor, buena conductividad térmica, baja resistencia al escape,

Alta eficiencia de filtración, fuerte resistencia a la presión, etc. Reducir la pérdida de potencia y el consumo de combustible del motor diesel.

La tasa de limpieza de las partículas PM2.5 puede alcanzar el 90-99%. El coeficiente de absorción de luz de emisión original ≤1,61m-1, más la captura de partículas Aosif

Después del concentrador, el coeficiente de absorción de la luz de escape ≤0.5m-1, de acuerdo con los requisitos nacionales de protección ambiental.

4. La ecuación de la reacción de regeneración del principio del receptor de partículas DPF se muestra en la Figura 1:

Figura 1 Ecuación de la reacción de regeneración de calentamiento del DPF

1 | NO 2+Soot(C) CO2+NO |

|

2 |  Soot (C)+O2 CO2 Soot (C)+O2 CO2

Soot:Refers to combustible organic black smoke particles, or toner: C |

3 |  NO+O2 NO 2 NO+O2 NO 2

|

5. AOSIF particle trap: regeneration principle, regeneration method and regeneration conditions

5.1 Principle of regeneration: When the black smoke particles captured by the DPF carrier accumulate to a certain extent, the exhaust back pressure of the DPF is relatively large, which can be Affecting the increase in power output and fuel consumption of diesel engines, it is necessary to effectively regenerate the intercepted carbon particles through effective methods.In order to achieve the effect of repeated use of DPF.

5.2 Regeneration method: Back-blowing (heating) regeneration, using DPF or CDPF, requires external regeneration conditions.

5.3 Regeneration conditions: back-blowing (heating) regeneration conditions: after reaching the set back pressure alarm, it needs to be disassembled for regeneration maintenance.

5.4 Regeneration process: During the entire working process of the diesel engine, the exhaust gas temperature is lower than 250 degrees, or the load is small each time it starts.For machines below 25%, it is recommended to use back-blowing heating for regeneration. When the diesel engine exhaust back pressure continues to exceed 15Kpa, it needs to be disassembled Come down for thorough cleaning and maintenance. The DPF regeneration temperature is between 600-730 degrees, and the soot particles collected in the DPF are at a reasonable temperature Direct oxidation and combustion, so that the DPF's ability to trap soot particles can be restored and can be reused.

5.5 Maintenance cycle: According to the original smoke exhaust value of the internal combustion engine and the working conditions, the maintenance cycle time is also different. Normal conditions After the back pressure reaches 15kpa, the DPF needs to be disassembled for a thorough cleaning and maintenance. After thorough maintenance or regeneration, it can be N Repeated use many times, the filtration performance is the same as the new product.

6 Requirements for the original condition of the diesel engine:

6.1 It is recommended that the smoke value measured by the opacity smoke meter under the free acceleration of actual work of the diesel engine is not more than 1.61m-1.

6.2 Diesel engines that match the particle trap have various performance indicators and components, such as cylinder pressure, fuel injection timing, uniform operation of each cylinder, good fuel pump and fuel injector plunger pressure and atomization, normal speed regulation, and oil The consumption is normal, the air filter is clean, and the exhaust pipe is connected without smoke leakage.

6.3 If the smoke value of the original diesel engine is ≥1.61m-1, the diesel engine needs to be overhauled, the fuel pump needs to be adjusted, the fuel injection nozzle needs to be changed, the valve need to be adjusted or replaced, etc. to reduce the emission of the diesel engine. Users need to arrange the maintenance unit for maintenance. Excessive smoke levels of diesel engines will easily cause carrier blockage.

6.4 If the original diesel engine exhausts blue smoke, it means that the engine is burning oil and the diesel vehicle engine needs to be repaired. Please arrange for the diesel engine maintenance unit to inspect or replace the cylinder liner, piston ring, valve, valve seat, valve guide, and turbocharger. Maintainer need to take the turbocharger assembly or repair kit. The diesel engine burns oil easily to cause DPF blockage.

7. Product performance and meeting standards

7.1 Filter material: ceramic carrier is used.

7.2 Connection mode: flange connection is adopted, which is convenient for disassembly and maintenance.

7.3 Product filtration efficiency: the treatment efficiency of soot particles PM (black smoke) is ≥95%.

7.4 Meet the national standard: GB36886-2018 "Exhaust Smoke Length and Measurement Method of Non-road Diesel Mobile Machinery", diesel engine is free to add

The smoke value measured by the opacity smoke meter under the fast state is ≤0.8m-1.

8.National emission standards and oil standards

8.1 Fuel usage requirements: please use the standard national five light diesel oil, the sulfur content of the diesel oil is ≤10ppm.

8.2 Please keep the original invoice for purchasing diesel and engine oil, which can be used as a reference for warranty.

8.3 The smoke value of the original diesel engine is ≥1.61m-1, please repair or adjust the engine in time. Large original smoke values are likely to cause vector insertion.

8.4 Requirements for the use of engine oil: low-ash engine oil is recommended. Grades above CH are recommended. The engine oil grade can also easily cause carrier insertion.

8.5 Make a record of operating hours or mileage each time you refuel.

8.6 National emission standards for the smoke emission value of diesel engine exhaust

◆ PM black smoke value (smoke value) of the national zero-emission engine ≥2.5m-1

◆ PM black smoke value (smoke value) of National No. 1 emission engine ≤2.5m-1

◆ PM black smoke value (smoke value) of National II emission engine ≤1.37m-1

◆ PM black smoke value (smoke value) of national three emission engine ≤0.8m-1

◆ PM black smoke value (smoke value) of national four emission engine ≤0.5m-1

◆ PM black smoke value (smoke value) of National V emission engine ≤0.3m-1

◆ PM black smoke value (smoke value) of National VI emission engine ≤0.1m-1